Acrylic fabrication involves the process of cutting, bending and polishing acrylic to create various retail display products. A more versatile alternative to glass, its crystal-clear appearance, durability, light weight composition and impact resistant properties offer a completely bespoke and effective solution for all retailers display needs.

At Harrison Products, our acrylic manufacturing processes are backed with extensive industry experience and an innovative forward-thinking approach, establishing us as both specialists and leaders in the field, regardless of the brief or industry. Our in-house acrylic fabrication facilities fitted with state-of-the-art technology guarantee market-best lead times irrespective of service type, product specifications or quantity requirements.

Cutting, bending and polishing

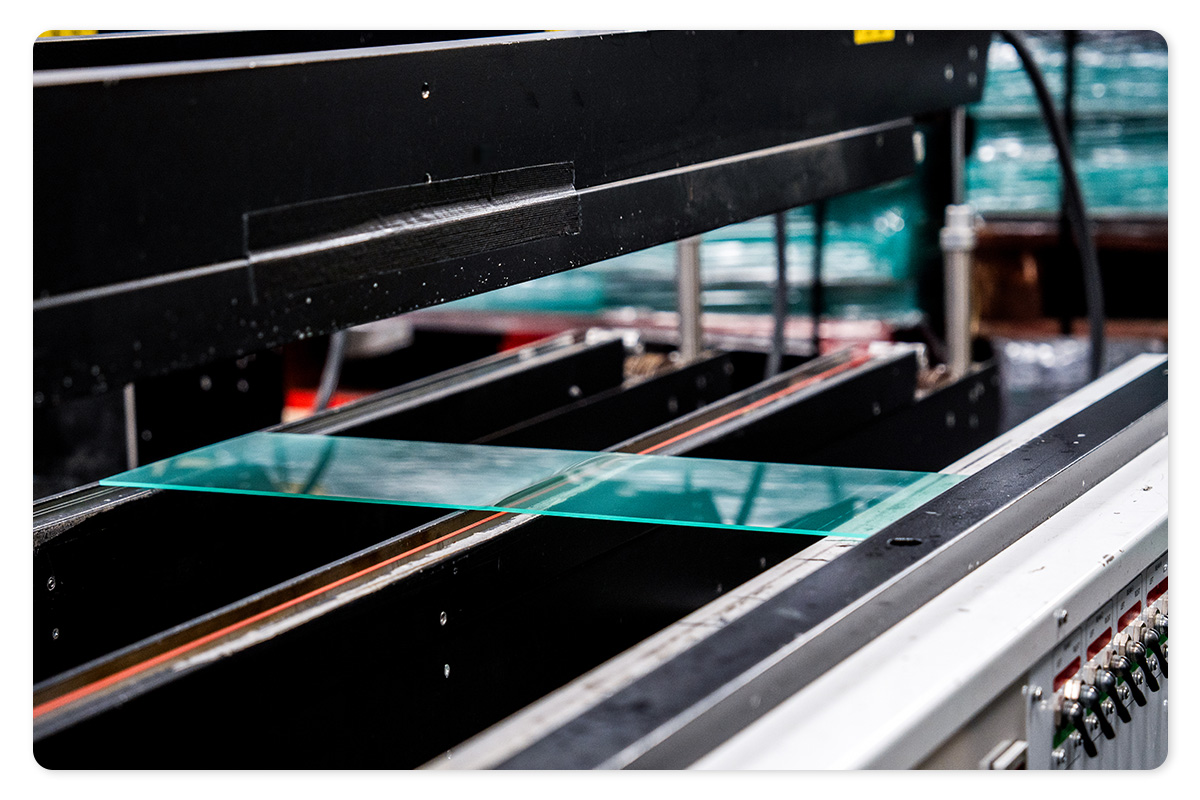

Our acrylic is cut using either computer numerical control (CNC) or lasers depending on the type of product and desired finish. CNC is a lower cost friction-based method, cutting diagonal, curved and straight lines with ease. For more intricate designs and finer details, our advanced laser cutters produce high precision, glossy finishes for all acrylic applications.

Once cut, flame and diamond polishing techniques are employed on products such as shelf risers to smooth sharp, dull or marked edges, for a sleek, glossy finish. Made from robust acrylic, our shelf risers are precisely cut and polished to order for flawless integration and simple instalment into any shelving space.

Our acrylic fabrication services extend beyond just cutting and polishing. Through heat application, we are able to soften and bend our plastic to any desired angle, creating an appealing, uniform curved appearance. Our acrylic angled sign holders, for example, are used to showcase single sided signage or point-of-sale products for easy reading at standing height. Featuring a flexible side slot for easy document replacement, these holders stand upright supported by a bend in the acrylic boasting both stability and functionality.

Mounting and fixtures

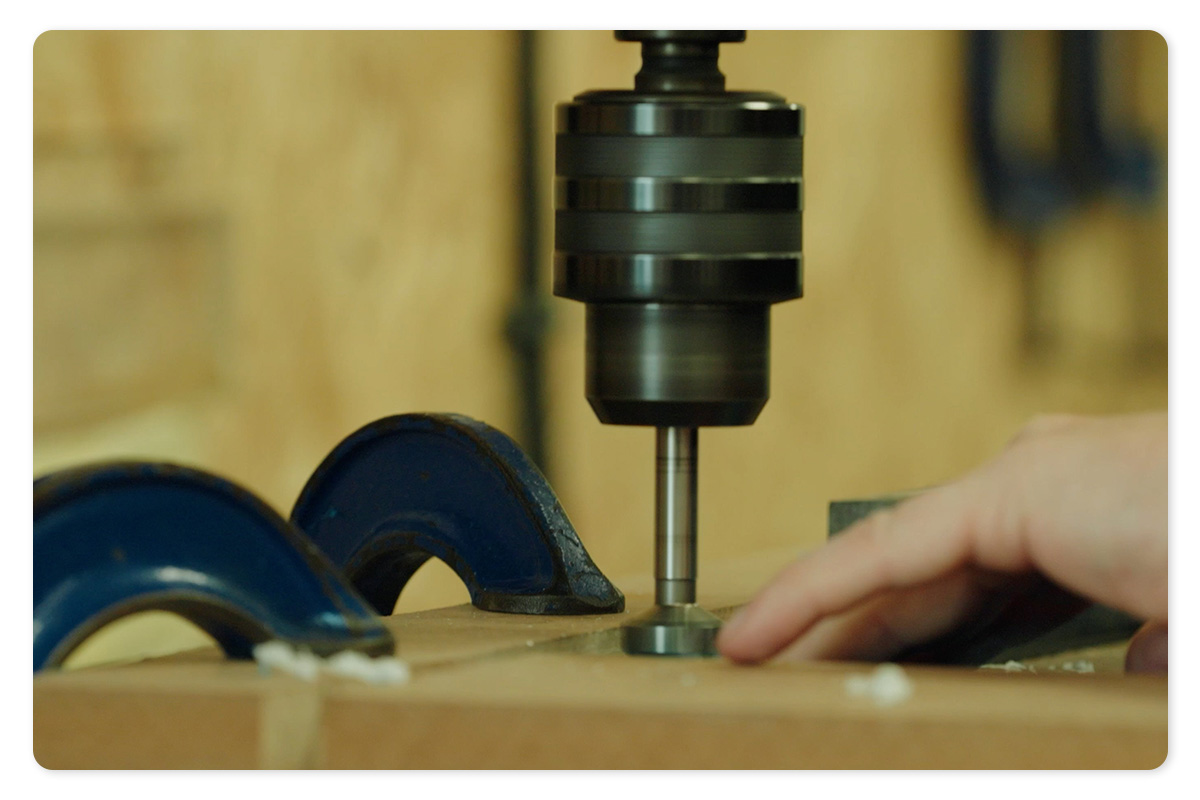

Similar to our cutting, bending, and polishing, all drilling requirements are processed in-house at Harrison. Our team oversees the drilling of accurate, custom-sized holes essential for the fitting of display mounting components. The care and precision employed by our team guarantee that all wall-fitted signage is secure and safe, irrespective of the surface, for a consistently professional and sleek presentation.

The addition of self-adhesive tape facilitates the flawless attachment of promotion signage onto temporary units. Our adhesive pocket sign holders, made from PVC, offer a quick and convenient solution for in-store installation. After inserting the desired poster into the holder and peeling back the self-adhesive strips on the short edge, retailers can attach the holder onto any surface by simply pressing firmly for a hassle-free promotional display.

The ultimate solution to retail display demands

At Harrisons Products, we pride ourselves on our comprehensive offering of acrylic products and fabrication services to meet every retail display need, promptly and efficiently. With a commitment to quality craftsmanship and materials, retailers can bid farewell to the frustrations of ill fitted display components and challenging installations.

For more information on our manufacturing processes, and how we can support you with bespoke retail display products, see our page on Acrylic Fabrication Services.